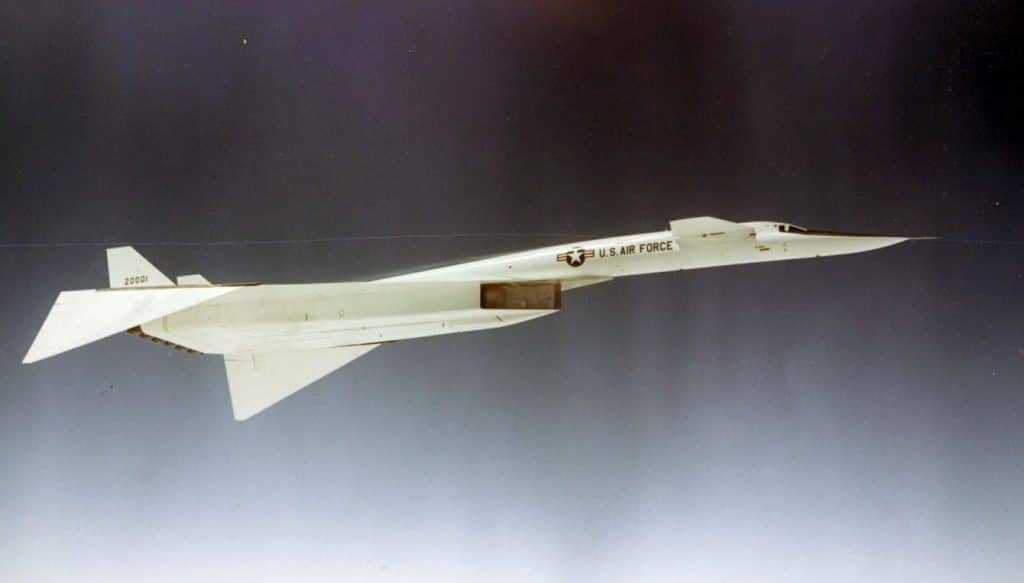

In the 1960s, the USAF operated two XB-70 Valkyries. The Valkyrie remains the world’s fastest bomber to ever fly. Each surpassed Mach 3, conducting research to test aerodynamics, propulsion, and other characteristics of large supersonic aircraft.

Each test vehicle flew many times. One of the XB-70 Valkyries tragically crashed later in the program. Before that incident, there were other challenges. Here’s the story of how one of the XB-70s avoided what could have been a disaster thanks to a team of engineers and a pilot with a paperclip.

Background of the XB-70 Valkyrie: A program that never was

The idea for the XB-70 Valkyrie was conceived in the 1950s. At the time, the US Air Force wanted a Mach 3 high-altitude bomber with a nuclear strike capability. Within a few years after conception though, the invention of Surface-to-Air Missiles (SAMs) and nuclear-armed ICBMs convinced the USAF to cancel the XB-70 Valkyrie program. No production craft were completed or flown.

However, the USAF ordered two jets from North American as test platforms for research purposes. The first XB-70 Valkyrie (AV-1) flew in Oct 1964, followed by the second (AV-2) in July 1965. Sadly, the second test vehicle was lost in a mid-air collision a year later with an F-104.

AV-1 continued flying research, but was transferred to NASA in 1967 to support the National Supersonic Transport Program. NASA handed the remaining XB-70 Valkyrie over to the National Museum of the USAF in 1969, where it is on display today in Dayton, OH.

XB-70 Valkyrie Problem Occurred Immediately on Takeoff

Before the tragic accident in the summer of 1966, AV-2 had another potentially catastrophic issue. On 30 April 1966, USAF Col Joe Cotton and North American test pilot Al White took off in AV-2 from Edwards Air Force Base. Their mission was to hit Mach 3 for 30 minutes.

With 6 engines and 168,000 pounds of thrust, they roared down the runway for departure, but it wasn’t long before a problem popped up. The nose gear was jammed. They had a short-circuit in the landing gear retraction system.

The 500,000-pound plane’s nose gear was blown back into the half-retracted gear well door, and the tires were also slashed. When they tried to lower the gear, they couldn’t because the hydraulic system failed. Even the backup electrical system for the gear was useless.

Landing a Cessna or Bonanza without nose gear is one thing. You’ll probably walk away from that. But doing it in a Valkyrie would likely be suicide. Without nose gear, the crew would be unlikely to survive due to the plane’s nose-up attitude and underbelly structure.

Conventional attempts to fix it didn’t help, time for Plan B

They decided to try some hard touch-and-gos, hoping to knock the tire back into its locked position so they could land safely. It didn’t work. They were flying for an hour trying to find a solution, and they were running out of options other than to bail out and lose the plane and possibly their lives.

Fortunately, engineers on the ground determined the problem and advised the crew to short-circuit the electrical system. So Cotton reached into his briefcase and pulled out a paperclip. He simply used it to reach in and short-circuit the breaker.

The problems weren’t over yet for the XB-70 Valkyrie

With the nose gear down and locked, Cotton and White brought AV-2 in for landing. On touchdown, 3 of the 4 main landing gear locked up, igniting in flames under the belly of the plane as it deployed its drag chutes. The jet came to a stop in spectacular fashion, but the crew and the plane survived to fly another day. Here’s the kicker… a paperclip saved a $750 million aircraft. Eat your heart out, MacGyver.

A paperclip saved a $750 million aircraft. Eat your heart out MacGyver.

“I am convinced we would have broken the plane to pieces if we had tried to land without the nose gear locked into position,” said White.

Cotton too recalled the day. “I’m sure anybody could have gimmicked up something to short across between the terminals, if they had the motivation I had.”