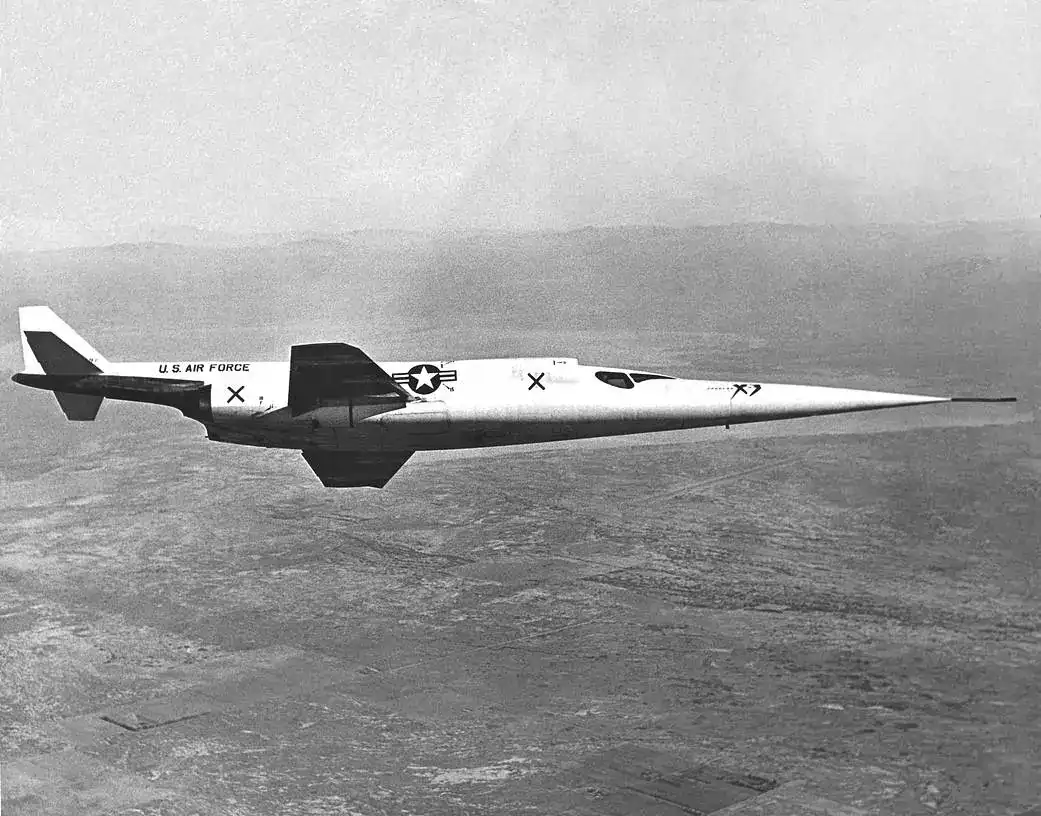

The United States developed the Douglas X-3 to reach Mach 2 and maintain an edge in the race to build the world’s fastest, most advanced fighter jets.

With its sleek shape and short wings, the X-3 featured a cutting-edge design. However, it fell short of expectations due to underpowered engines and control issues. Although it never achieved its original performance goals, the X-3 contributed valuable data that improved the safety and design of future aircraft.

Supersonic Planning Began in 1941

In 1941, the US Army Air Corps began exploring the possibility of supersonic flight and asked the Douglas Aircraft Company to examine whether breaking the sound barrier was achieveable. During the next several years, the service remained committed to the idea as Douglas continued developing a potential design.

The project gained momentum, and in 1945, Secretary of War Henry Stimson approved a request for Douglas to develop an aircraft capable of reaching Mach 2. It was also required to fly for at least 30 minutes and take off and land under its own power. This requirement set it apart from the rocket-powered Bell XS-1, which was launched mid-air from the bomb bay of a B-29 bomber and glided to a landing when its fuel ran out.

Douglas Aircraft Company Produces Innovative X-3 Design

In 1949, Douglas finalized its concept aircraft design, named Model 499-D, with a service title of “X-3.” The company agreed to build two X-3 aircraft. The original specifications called for twin engines, a length of 66 feet 10 inches, a wingspan of 22 feet 8 inches, and a maximum weight of 22,400 pounds.

Douglas planned for the airframe to be mainly aluminum alloy. They also intended to use stainless steel, molybdenum, and magnesium alloy for the surfaces that would face intense heat. However, later that year, the Air Force approved a request from Douglas to substitute titanium on the tail boom, afterburner, and tail cone sections. These changes reduced the aircraft’s weight by 395 pounds.

Another distinctive feature of the X-3 was its long, thin nose cone. It housed the nose landing gear, flight test instruments, and other electrical systems.

Inadequate Engines Keep X-3 from Reaching Mach 2

While the X-3’s basic design appeared modern, sleek, and capable of reaching high speeds, its engines became one of its major flaws. Douglas Aircraft’s initial design was for the X-3 to have the newly designed turbojet, the Westinghouse J-46, with an afterburner. This design would produce 6600 pounds of thrust with afterburners.

By 1948, however, Douglas found that the J-46 was still under development and not ready for the X-3. They then decided to replace the J-46 with the J34-WE-17. This engine had similar dimensions to the J-46 but could only produce 4850 pounds of thrust. This flaw left the aircraft “severely underpowered” and unable to reach its Mach 2 performance goal.

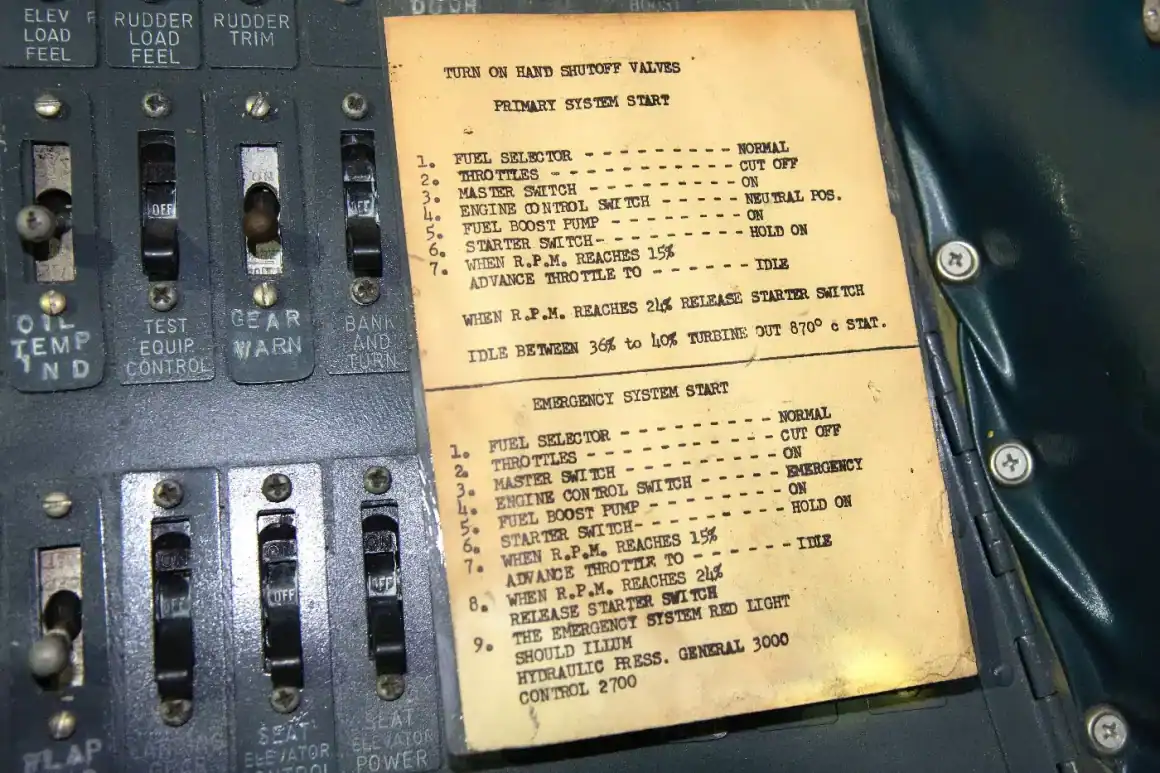

For its first supersonic flight, the pilot had to put the aircraft into a 15-degree dive to reach Mach 1.1. The X-3’s fastest flight was on 28 July 1953, reaching Mach 1.208 in a 30-degree dive. Another problem with its engines was that its takeoff speed was 260 knots.

Control Problems Proved Challenging for Douglas X-3 Pilots

The Douglas X-3 also had significant control problems during flights.

After the first test flight on 20 October 1952, test pilot William Bridgeman stated, “This thing doesn’t want to stay in the air.”

Bridgeman landed at 240 miles per hour and said he was happy the dry lakebed runway at Edwards AFB gave him plenty of room to slow down.

After the 25th test flight on 2 December, the Air Force received the single Douglas X-3. Pilots Chuck Yeager and Lt. Col. Frank K. Everest each made three additional test flights. After finding the controls “sluggish” at low speeds, Everest called it “one of the most difficult airplanes I have ever flown.”

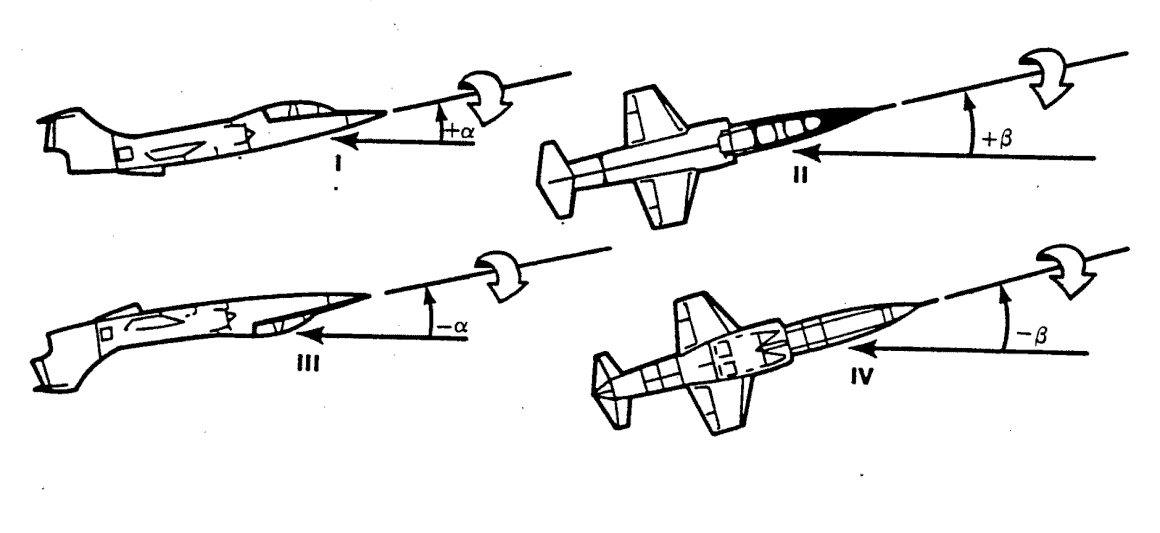

A year later, on 27 October 1954, pilot Joseph A. Walker was flying a test mission in the X-3. The flight was a series of tests of the jet’s lateral and directional stability. With relatively “short and stubby wings,” most of the X-3’s mass was centered along its long fuselage.

Sudden Uncontrolled Movements

During the flight, Walker was flying at Mach 0.92 at 30,000 feet and made a left roll. As the X-3 made the roll, the nose suddenly pitched up 20 degrees and yawed 16 degrees. Walker got it under control and prepared for the next test maneuver.

He went into a dive and accelerated to Mach 1.154. He then made a left roll, and the nose pitched down and then up while also sideslipping. These sudden movements loaded the fuselage with higher than normal g-forces. Walker managed to control the aircraft and landed safely. The post-flight inspection found that the X-3 had reached its maximum load limit and could have broken up if the g-forces had been higher.

Roll Coupling Results in Grounding of X-3

Engineers determined that the X-3 had undergone “roll coupling” or “roll divergence.” This occurs when an aircraft makes a maneuver around one axis and causes an uncommanded move in one or two others. Following this incident, the Air Force grounded the X-3 for almost a year and never tested its roll stability limitations again.

Around the same time, several Air Force F-100As also experienced roll coupling, resulting in three crashes and two fatalities.

Walker completed ten additional flights in the X-3, with his final flight taking place on 23 May 1956. Shortly afterward, the Air Force retired the aircraft and transferred it to the Air Force Museum.

The X-3 Still Had Some Successes

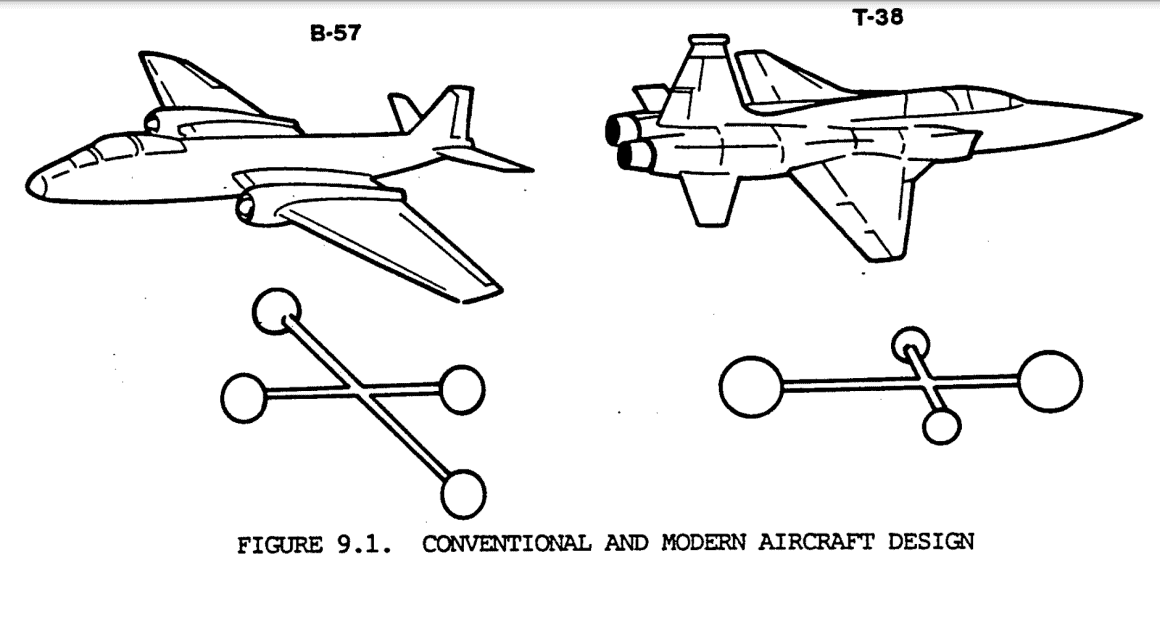

Although the Douglas X-3 never achieved its goal of flying at Mach 2, it was far from a failure. The program yielded valuable insights, particularly about roll-coupling, which led to important design changes to the F-100 and F-104. The X-3 was also one of the first aircraft to use titanium. Additionally, its unusually high takeoff and landing speeds spurred advancements in aircraft tire technology.