Kit Planes Built with Hard Work and Support from EAA Community

Buying and assembling your own kit plane might seem difficult, but it’s possible with some basic mechanical skills, hard work, and especially support from other pilots and builders.

Bearhawk B Kit Plane

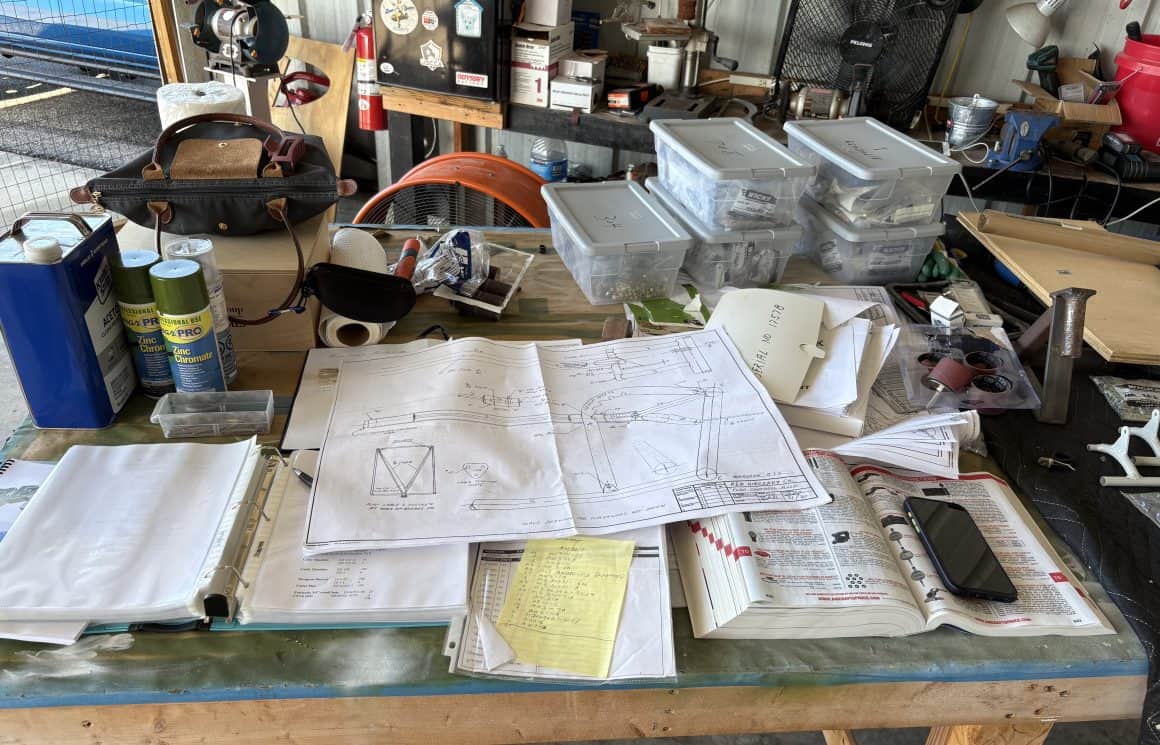

Bob Willaford and Lauren Thomas are building a Bearhawk “B” kit plane in a hangar at Page Field in Fort Myers, Florida. They received the kit in May and hope to complete the project by June 2025. Bob previously built and piloted a Vans RV-9, and Thomas is working on her private pilot license.

The Bearhawk kit came with the basic airframe, tail suspension, brake system, wings, fairings, windshield, and engine mount. They purchased it as an ‘Advanced quick-build kit’ with some parts already assembled. They had to buy and order the engine, propeller, avionics components, tires, paint, fabric, and other items.

Builders customizing their planes

They also ordered their instrument panel from Stein Air, which they could customize with the displays and other components they wanted. According to Thomas, one of their biggest challenges has been scheduling the delivery of some items and scheduling the delivery of items on back order. For example, they ordered the engine, a Lycoming IO-390, several months ago and expect it to arrive in January.

For the Bearhawk project, they also had to learn some new skills. The Bearhawk has fabric covering the fuselage and control surfaces, and the wings are aluminum. Willaford and Thomas recently went to a class at Stewart Systems in Wooster, Ohio, to learn fabric covering and painting techniques for their kit plane.

They described how they learned to spray the fabric with multiple coats of different substances, including an eco-coat, ultraviolet protection, primer, and paint. These soak into the Dacron fabric and fill in the weave, producing a stiff, durable, and light surface. In addition to spraying, they also had to cut the fabric to fit the aircraft surfaces.

Building kit planes with support from other EAA members

Willaford and Thomas are not alone as they work on the Bearhawk. They receive support from fellow Experimental Aircraft Association (EAA) Chapter 66 members at Page Field. On a recent Sunday, Bob was designing and fabricating an aluminum tray to mount under the instrument panel, while Thomas was working on the rudder and elevators.

Throughout the day, other members of EAA 66 stopped by the hangar. Some offered help, others asked questions about their kit planes, and others just wanted to talk about aircraft. A young man, Blake, showed up and helped Thomas remove the packing materials from the rudder. Another EAA member, David Burns, visited and offered to help with the equipment tray.

Van’s RV-10

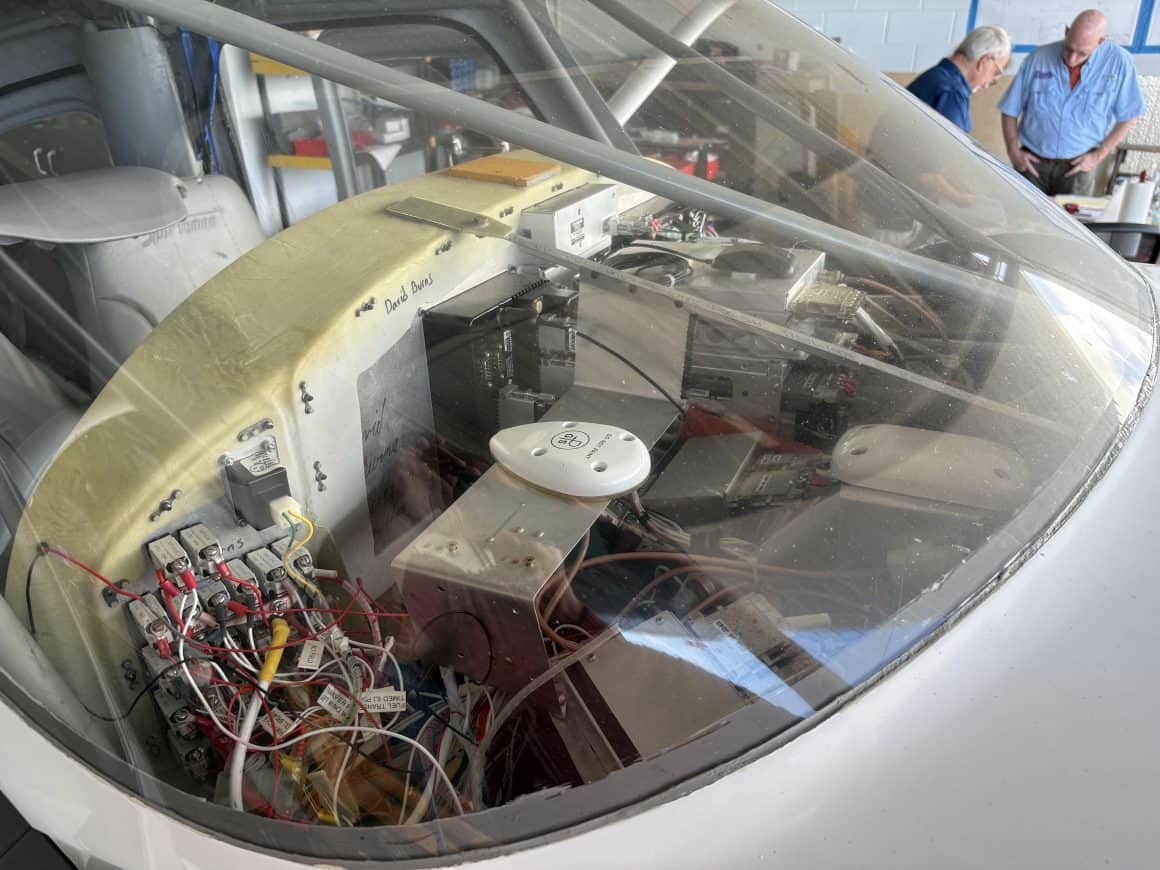

Burns is building his own kit plane, a Van’s Aircraft RV-10, in the hangar bay next to Willaford and Thomas. In the same hangar, Burns keeps the Sportsman he built from a kit several years ago.

When Burns saw that Willaford was working on the equipment tray, he brought him to the Sportsman to show him how he configured the instrument panel and tray. Burns removed the cover from the aircraft’s dashboard so they could examine the parts.

Burns explained how he had attached hinges to the bottom of his tray to allow it to drop down and provide easy access, and Willaford decided to use the same design on the Bearhawk.

Burns explained a customization he made on the Sportsman to install a timer to control fuel flow from the four tanks on the aircraft. On his RV-10, he chose to buy a Lycoming 540 engine. Customization and making modifications seem to be some of the appeals of building kit planes.

One gets the sense that EAA members collaborate and consult with each other quite a bit on their kit planes. Willaford said the EAA 66 has a “parts and pieces” area with specialty tools members can use. All of this support and knowledge sharing seem to be some of the most important aspects of building these planes. This is a real community of airplane builders and pilots.

Van’s RV-14 kit plane

Dan Ruehl is another Florida pilot who built his own kit plane. He built his Van’s RV-14, working on it for two years in his garage and completing it in his hangar, which is only about five minutes from his house. Altogether, it took him just under four years to finish the aircraft. Like Willaford, Thomas, and Burns, Ruehl received help from members of EAA 66 as he worked on the RV-14.

“I did surround myself with experienced mentors, so if I had a question, I had lots of options for advice,” said Ruehl. “I think that was the smartest thing I did during this entire build.”

Community of kit plane builders

Neither Willaford, Thomas, Burns, nor Ruehl is a commercial pilot. They all had other careers and now enjoy being around aircraft. Willaford was a fireman, Thomas was a Nurse, and Ruehl is still an air traffic controller. Burns calls his involvement in aviation a hobby. None of them fly professionally. Instead, they enjoy building and flying their own kit planes. But those aren’t the only reasons they do this. They also enjoy working together and helping each other to build and fly.