In the 1960s, the development of high-performance reconnaissance cameras offered greater resolution, but at a price.

Many of these systems were large and heavy, and the current high-altitude spyplane of the time, the first-generation variants of the Lockheed U-2, were unable to carry them. One of the premier recon optical systems developed at this time was the General Dynamics HIAC-1- a long-range, oblique camera with a focal length of 66 inches that allowed stand-off reconnaissance from high altitudes.

First camera attempts were too heavy

The first examples of HIAC-1 were heavy- the prototype camera system weighed over 3,500 lbs, much more than any other camera system in use at the time (excepting the very big Boston Camera carried by the B-36 and C-97 in the 1950s that weighed 3 tons and had a focal length of 240 inches). The only aircraft in the USAF inventory that could carry the HIAC-1 was the RB-57F, a modification of the Martin B-57 Canberra.

In 1962, General Dynamics in Fort Worth, Texas, had the contract to maintain the RB-57D fleet, which suffered from wing spar fatigue. Since General Dynamics had acquired quite a bit of experience in working on the long-span RB-57Ds, they were asked by the Air Force for an evolved version of the D that could fly higher, carry a heavier load (like the HIAC-1), and not have the same wing spar problems that plagued the RB-57D.

The RB-57F was the result- with a longer wing, more powerful TF33 turbofan engines, and auxiliary J60 turbojets, it was what the USAF needed until the later generation of U-2 spyplanes entered service. In fact, NASA still uses three RB-57Fs today.

Over the course of the RB-57F’s operational career, Israel had repeatedly requested to obtain the RB-57F and the HIAC-1 for its own reconnaissance needs. Still, the requests were always denied by the US State Department and the Defense Department because the technology used in the RB-57F would upset the strategic balance in the Middle East.

However, a compromise was reached- by 1971, the HIAC-1 had been steadily improved and lightened to the point that it weighed just under 1,500 lbs, and that a pod-mounted HIAC-1 carried by the McDonnell Douglas F-4E Phantom, already in the Israeli inventory, would be permissible.

Improvements were slow but sure

Also developed by General Dynamics, the pod-mounted HIAC-1 was designated G-139 and underwent an intensive flight test program with a USAF RF-4C aircraft and the first G-139 pods were delivered to Israel in October 1971.

The Israelis found the G-139/HIAC-1 system useful as it allowed the Phantoms to get imagery of Egyptian defenses along the Suez Canal without having to enter the SAM umbrella. But there was a significant issue: the pod was still a heavy store, and it generated a significant amount of drag- it limited the Phantoms to a maximum speed of Mach 1.5 and a maximum altitude just under 50,000 feet, not to mention the challenge of handling a G-139-laden F-4E at high altitude.

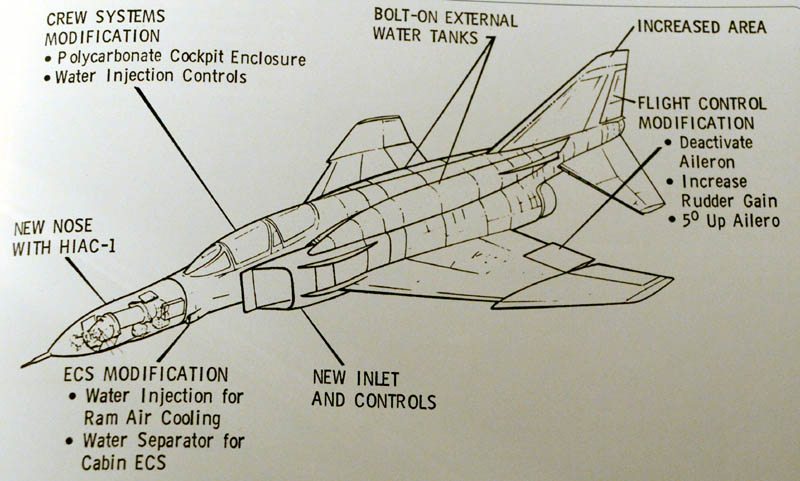

As a result, the special projects division of General Dynamics began work in January 1972 on ways to improve the F-4E’s performance to offset the burden of carrying the pod.

The first improvements came with getting the most out of the Phantom’s J79 engines. Engineers found that the Phantom’s intakes were limiting the performance possible from the J79. A new inlet was designed that was not only larger than the standard F-4 inlet, but it featured a new shape that better managed the airflow to the engines with a series of new variable-geometry ramps. The standard Phantom inlet did have a variable geometry ramp. Still, it was much simpler than the General Dynamics design, which featured a large bypass door downstream from the inlet to help manage the internal shockwaves that helped slow the air down before reaching the engines.

Aerodynamic improvements made through testing

A series of vortex generators down the inlet also helped improve engine performance. The second improvement was based on 1950s research done by NASA’s predecessor agency, NACA, called pre-compressor cooling (PCC). PCC was a form of water injection, but used the water to cool the inlet air before it reached the engines. By reducing the inlet air temperature, it increased the mass of the air, akin to taking off on a cold day- engine air flow and thereby thrust would be increased. At high altitudes, PCC would boost engine performance starting at Mach 1.4 as the inlet air started to heat up due to friction.

General Electric, the manufacturer of the J79, was less than enthused about General Dynamics’ work on PCC, but did provide some consultations. Work had already been done with PCC on another of General Dynamics’ products, the Convair F-106 Delta Dart, but it was never incorporated into the design. In addition, the USAF’s Arnold Engineering Development Center in Tennessee had tested PCC in engine test cells with both the J57 and J75 engines.

One J75 engine was run at maximum afterburner for 40 hours with PCC! It had also been looked at by Vought for the aborted F8U-3 Crusader III design (though never flown), and McDonnell had used a rudimentary PCC system in 1962 to break several world speed records with the pre-production F-4 Phantom.

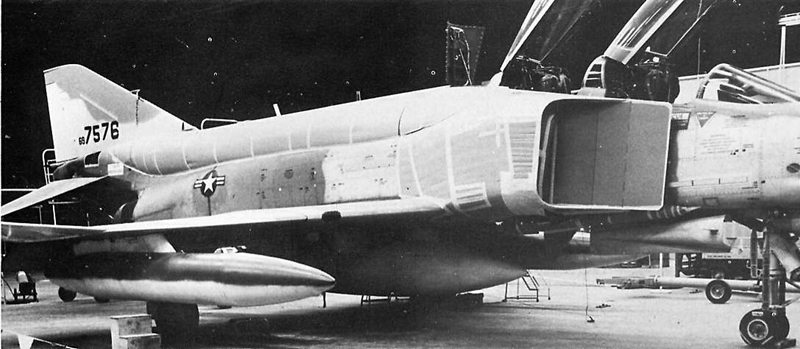

Based on all this body of work, General Dynamics refined the PCC system so that the water droplets were very fine at 10 microns to cool the air without having any pooling of water in the engine. Two large water tanks were installed on external blisters along the sides of the F-4E, each blister with three tanks. Each blister could carry 2,500 lbs of demineralized water- since the interior of the Phantom was pretty packed as it was, scabbing these blisters on the fuselage eased the modification and engineering process.

More Refinements became the F-4X

General Dynamics’ modifications led to this version of the Phantom being unofficially designated the F-4X- at this point still carrying the large G-139/HIAC-1 pod underneath on the centerline station. With Israeli funding supplementing internal corporate, work on the F-4X continued through 1972 and refinements to the PCC system and inlets led to a calculated increase in the J79 thrust at high altitude well over 150 percent!

On 12 April 1973, the company formally submitted the F-4X proposal to the USAF. The USAF then provided additional funding for more work. The USAF was using the podded HIAC-1 system for stand-off reconnaissance in Korea and encountered the same issues the Israelis were having using standard Phantoms with the large camera pod.

The following year, the design was further refined, but with the Israelis continuing to have misgivings about using the HIAC-1 in a pod, the design leap was made to incorporate the HIAC-1 into F-4X’s nose. With the latest HIAC-1 versions getting even lighter than the 1,500 lb version used in the G-139 pod, integrating the camera into the nose improved performance by eliminating the drag-inducing pod.

The F-4 Speed Demon Was Born

Designated RF-4X, this version of the Phantom was now capable of cruising at Mach 2.4 at high altitude with burst capability to Mach 3.2. This level of performance now began to alarm the US State Department- up to this point Mach 3+ aircraft we

It was the sole purview of the United States and the Soviet Union, and in some diplomatic circles, there were concerns about the Israelis integrating nuclear weapons delivery with the RF-4X. General Dynamics removed the AN/APQ-120 radar from the nose to allay the State Department’s concerns, which would now only house the HIAC-1 and its associated environmental control systems. Permission to sell the RF-4X to the Israelis was approved, and in November 1974, an Israeli F-4E was flown to General Dynamics in Fort Worth for a mock-up study.

For five months, engineers used the F-4E as the basis of a full-scale mock-up created with cardboard and tape- both the Mach 3 intakes and the PCC water tanks were mocked up on the Phantom on one side, as well as the modified nose housing for the HIAC-1 camera.

F-4X Could Have Been Faster Than An F-15

By 1975 several factors were now working against the RF-4X, the biggest of which was time. The Israeli Air Force wanted the system as soon as possible but it was clear that the integration of the camera, intakes and PCC system was going to take more time than originally estimated.

With the McDonnell Douglas F-15 winding up its flight test program and soon to become operational in the following year to replace the Phantom in USAF service, it was politically unpalatable to keep funding the RF-4X, which offered a level of performance that exceeded that of the Eagle in some flight regimes.

The USAF insisted upon further studies of the PCC system even though there were already nearly 20 years of data on pre-compressor cooling, some of which was done by the USAF itself. Compounded with the engineering delays, Israel and the RF-4X proponents in the USAF lost interest, and it was quietly canceled later that year.

Canceled!

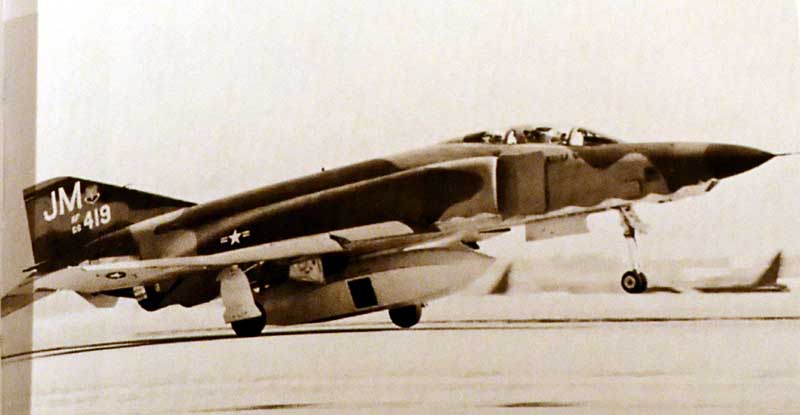

Despite the cancellation of the RF-4X, General Dynamics did continue work on just the nose-mounted HIAC-1 component of the design for Israel. Three F-4E Phantoms were modified as F-4E(S) aircraft and delivered to the Israeli Air Force from late 1975 to early 1976. It turned out that the Israelis were unable to fund the RF-4X in its entirety and were only able to afford the HIAC-1 component.

As a result, the three F-4E(S) aircraft had standard J79 engines. In IDF service, the HIAC-1 was code-named “Shablul”, the Hebrew word for “snail”. The first operational flights began in 1976, with the aircraft capable of flying at 60,000 feet at Mach 1.9. The pilot and systems officer wore full pressure suits from the David Clark Company, which also made the pressure suits used by USAF U-2 and SR-71 crews and Space Shuttle crews.

Many of the missions flown remain classified, but it is known that Iraq was a frequent target through the 1980s. One of the aircraft is now on public display at the Israeli Air Force Museum.

Source/Photos: Israeli Phantoms- The ‘Kurnass’ in IDF/AF Service 1989 Until Today by Andreas Klein and Shlomo Aloni. Double Ugly Books/AirDOC, 2009, p44-70.