Eat Your Heart Out MacGyver! This Avgeek Built a RC Plane From a Broken Wall Heater

Watch how Southwest Airlines Painted Their Missouri One 737-700 Plane

Southwest is known for their ‘free-spirited’ image. They embraced hot pants in the ’70s, Shamu in the ’80s, and state flags beginning with Lone Star One in 1990 and continuing with California One, Nevada One, New Mexico One, Florida One, Maryland One, Illinois One and now Missouri One in 2015. Missouri’s state flag is extremely intricate for a paint scheme. This time lapse video, produced by Southwest Airlines, shows the sheer amount of skill and patience it took to paint the jet.

[youtube id=”zLKFVIbVEfk” width=”800″ height=”454″ position=”left”]

Could A Private Pilot Land An Airliner? Let’s find out!

Ever since Captain Oveur ate fish in the movie “Airplane”, #avgeeks have wondered if they could successfully land an airliner in the event that both pilots somehow passed out. Avgeekery’s friend Steve Thorne recently went to the Delta Flight Museum to find out by signing up to fly in their Level-D (full motion) 737-200 simulator. Below is his account with video!

As a weekend warrior private pilot, I’ve always wondered about the challenge of being handed the controls of an airliner. (it’s actually been more of a fear really, as I had little confidence that I could handle it.)

I got to test that theory recently!

We produced a 2 part series flying the 737-200 full motion level D sim at the Delta Flight Museum in Atlanta!

Part1 – Take off & Stall:

[youtube id=”JosrpU8BCRY” width=”800″ height=”454″ position=”left”]

Part2 – Approach and Landing:

[youtube id=”_7y7WVW0qLM” width=”800″ height=”454″ position=”left”]

If you’re interested in more flying films produced from the perspective of a self-analytical private pilot, flying for fun, but striving for professionalism, check out www.FlightChops.com

– we’ve produced over 75 videos, and release a new one every 2nd Friday

Umbrellas Fly as This Blue Angels F/A-18 Goes Low and Fast

We love flyovers at Avgeekery. Even after seeing hundreds of them on video and live, we have to say that this one is by far the best. Watch as Blue Angel #5 performs a low pass flyby over the crowd at Pensacola Beach. The jet sneaks by flying low, fast, and precise. The poor people on the beach never saw it coming. The crowd reacts with excitement as beach umbrellas blow everywhere! It’s an awesome testament to the power and speed of the mighty F/A-18.

Watch the beach umbrellas fly!

[youtube id=”_ba2wWgc8cU” width=”800″ height=”454″ position=”left”]

BONUS: Here’s another view of the same flyby.

While you don’t see the tents and umbrellas fly, it’s still impressive to watch.

[youtube id=”lnwYwRoVYy0″ width=”800″ height=”454″ position=”left” alt=”no umbrellas”]

Looking for more videos like this? Check out our page!

We post new videos and news stories every day. If you aren’t a fan of our Facebook page, why not?

Click here to view our Facebook page: Avgeekery.com on Facebook

Why Is This F-18 Taking Off On A Road?

Why would an F-18 take off on a road? It might look crazy but this crew is just practicing a capability and utilizing what’s known as a highway airstrip. A nation’s air force is only effective if they can get the planes off the ground. It is assumed that some of the first targets of a war would be the airfield. Highway airstrips were built during the cold war. Segments of straight, reinforced concrete roads capable of landing aircraft are strategically located throughout Europe. These auxiliary strips allow aircraft to take to the skies in the event that the primary airfields are rendered unusable.

[youtube id=”bNuVCvIGKxE” width=”800″ height=”454″ position=”left”]

Bus Crashes Into ATR Turboprop in India

File this as a “WTF” moment! A bus driver for Air India rival Jet Airways fell asleep at the wheel on December 21st at Kolkota Airport in India. He had a very rude awakening as his bus rammed into a parked Air India ATR-72 aircraft. Fortunately, there were no passengers on the bus or the plane. The bus driver was not injured. According to India Today, it took five days to bring in a crew to separate the bus from the vehicle.

Learn How To Fly a P-38 in this Vintage Training Video

[youtube id=”Q_DqFAbtrps” width=”800″ height=”454″ position=”left”]

No pilot enjoys training videos or computer based training. If you have to sit through the training, it might has well have cartoons. The Lockheed P-38 training video is actually informative and mildly entertaining. The Lightning is an amazing aircraft. As an avgeek, it’s fascinating to learn about the flying characteristics of the Lightning. Spoiler alert: Shut an engine down on the Lightning and she flies just fine!

This video was masterfully restored and colorized by Zeno’s Flight Shop.

Legendary Pilot Bob Hoover Flies One Last Roll Over Edwards in a Saberliner

Legendary pilot Bob Hoover passed away on October 25, 2016. This is a profile that we did on him in 2015.

—————-

Late last year, Air Force test pilot Bob Hoover took to the skies in a Frys.com Saberliner-60 doing ‘one last roll’. Hoover is a living Aviation legend. He personally knew and interacted with folks like Yaeger, Jimmy Doolittle, Eddie Rickenbacker, and even Orville Wright himself. Born in 1922, Hoover first earned heroic status when he took to the skies during World War II. He became a POW after his Spitfire was shot down over southern France after a malfunction. After enduring 16 months of captivity, he escaped by stealing a Focke-Wulf 190. After the war, Hoover became a test pilot for the Air Force, flying chase ship for Chuck Yeager during Yeager’s famous X-1 flight that broke the sound barrier and teaching tactics over Korea.

[vimeo id=”80041004″ width=”800″ height=”454″ position=”left”]

Bob Hoover is best known for his flying prowess in the air show circuit. He flew the P-51 Mustang and later the Aero Commander. During air shows he would wow crowds by flying aerobatics in what was thought to just be a turboprop commuter aircraft. He even once poured a glass of tea while doing a perfect barrel roll (see video below).

What makes this flight special is that Hoover had not publicly flown since 2000. His medical was revoked in the mid ’90s due to health concerns. He briefly regained his medical but retired at the turn of the century. As evidenced by this video, 93 year-old Hoover still has what it takes to be a ‘pilot’s pilot’.

You can learn more about Bob Hoover by checking out the Bob Hoover Project. A preview of the film is below:

[youtube id=”PzBiMQNc4tA” width=”800″ height=”454″ position=”left”]

Airborne Formations of People: Air Force Academy Prepares For National Championships

[youtube id=”ToYl0XwwjNQ” width=”800″ height=”454″ position=”left”]

Do you get to jump out of a C-17 at your college? The Air Force Academy’s ‘Wings of Blue’ Parachuting team released a video highlighting their training leading up to their competition at the National Collegiate Skydiving Championship. This year’s championship is being held this week at Florida Skydiving Center in Lake Wales, Florida.

The primary mission of the Academy’s jump program is to train cadets how to successfully free-fall jump out of a plane. The Air Force Academy program is unique because it is the only program in the world where the student’s first jump is solo. In addition to running the training program, cadets selected to be jumpmasters form the prestigious “Wings of Blue” team. The Wings of Blue are broken up into two teams–a demonstration and a competition team. The demonstration team performs at public, sporting, and military events. The competition team competes in various competitions around the world during the year.

BRRrrt! Five minutes of real A-10 Cockpit Footage and it’s Glorious!

The A-10 Warthog has been accused by its critics of being slow, outdated, expensive, and past its prime. The Air Force even tried to retire it this past year. They failed. Congress woundn’t allow it and for good reasons. This video made by the 25th Fighter Squadron gives an insight into why.

The A-10 is an amazing machine. The structure of the aircraft is built around a 30mm cannon with a titanium armored bathtub structure that protects the pilot. The Warthog is a tank in the sky. The A-10C provides close air support for troops in close contact with the enemy. The jet is a key contributor to the current US campaign against ISIS in Iraq.

[youtube id=”H4LOGfuuugc” width=”800″ height=”454″ position=”left”]

Video Proof Why You Should Always Be Ready For A Go-Around

Most pilots breathe a sigh of relief when they break out of the clouds and see the runway. But a landing is never guaranteed until you turn off the active runway and the spoilers are stowed.

Check out this video below of this Boeing BBJ (737 business jet) attempting to land. In the video, you’ll clearly hear ‘minimums’ with the runway still visible. This is the decision altitude where a pilot would normally commit to landing or go around. Even after the decision altitude, the pilot must still have the runway in sight at all times. In this case, the shower obscured the runway. The BBJ crew made the right decision to go around.

In an era of aviation where critics blast pilots for being nothing more than ‘system operators’, this video demonstrates why pilots are actually skilled professionals who command complex machinery in dynamic and dangerous environments. Split second decisions like this one keep passengers safe.

[youtube id=”vtlS0sxFlHk” width=”800″ height=”454″ position=”left”]

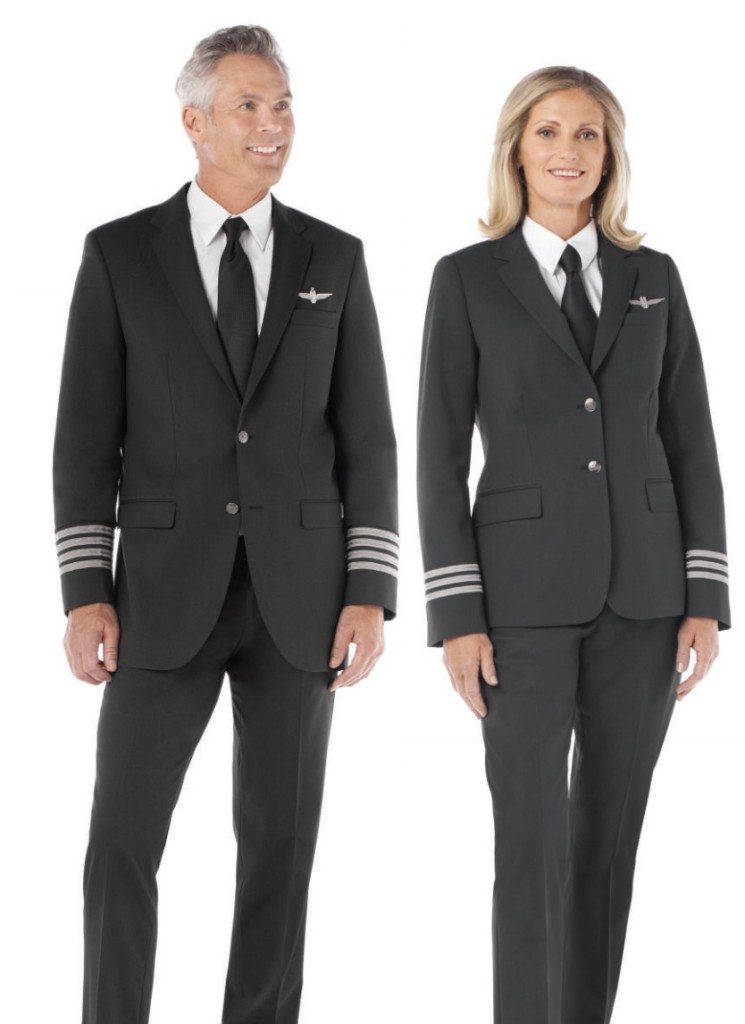

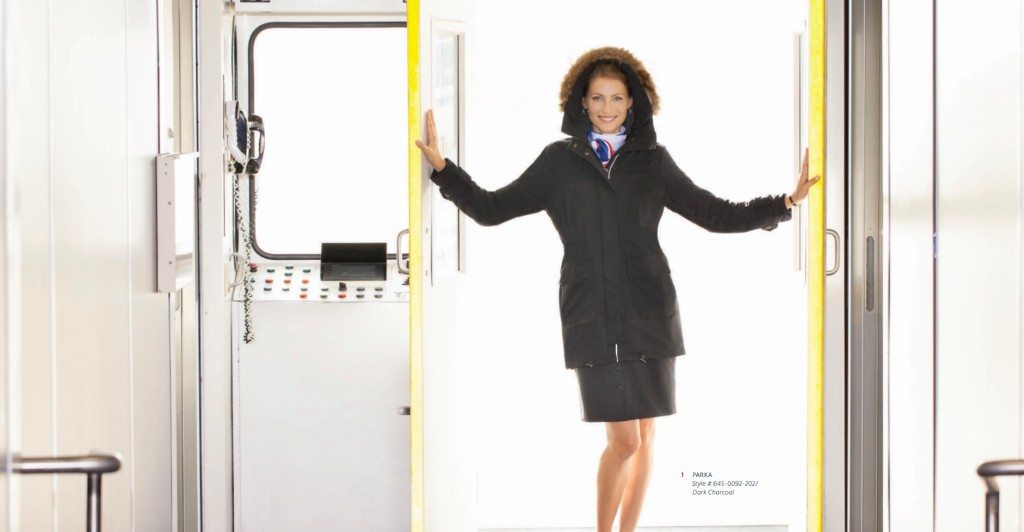

American Airlines Introduces New Uniforms

In a move that was widely expected, American Airlines unveiled new crew and employee uniforms this past week. The update will be the first uniform refresh for the newly combined company. Previously, American Airlines had not updated their uniforms in over 20 years. To be frank, American Airlines current uniforms are very dated. This will be a welcome refresh to an airline that has undergone an extensive brand refresh in just the past two years to include a new logo, paint scheme and branding. It follows uniform updates by the other major US carriers-United, Delta, and, Southwest.