Coastal Georgia’s first air show in twenty years is poised for take-off over Brunswick this weekend as the Wings Over the Golden Isles hosts the Navy’s Blue Angels, F-22 Raptor, and many more military and civilian aircraft.

The two-day event actually begins with a twilight air show Friday evening featuring the F-22, civilian aircraft, and followed by a concert lineup headlined by the southern rock band .38 Special.

This air show’s star-studded lineup includes the Navy’s own flight demonstration team the Blue Angels, who is expected to draw in an estimated 70,000 attendees. The Blue’s six blue and yellow F/A-18C Hornets will take-off at around 3:00 p.m. each day to begin their flight demonstrations.

The Delta Team will split into a Diamond and two solos minutes later as they perform nearly 30 maneuvers demonstrating the handling characteristics of the Navy’s Hornet aircraft. Stay alert for the solos’ famous sneak pass from behind the crowd.

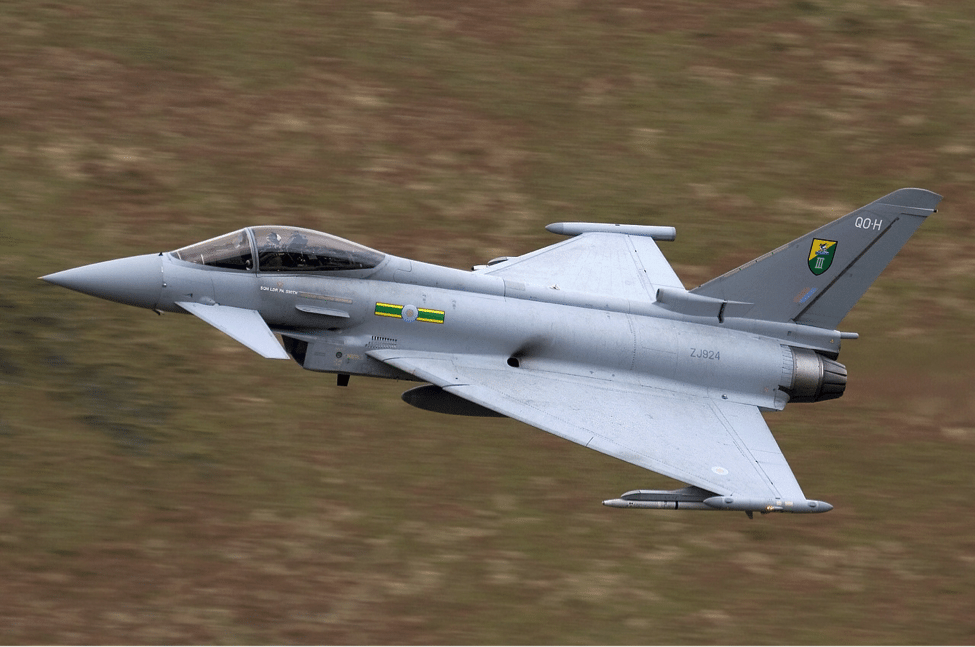

The Air Force F-22 Raptor will perform over the Golden Isles as the popular 21st century stealth jet demonstrates many of its military maneuvers at low altitudes. Raptor pilot Major Dan “Rock” Dickinson will put the F-22 through many gravity defying air strike maneuvers, and will later soar wingtip to wingtip with a P-51 Mustang during the hugely popular Heritage Flight.

Golden Isles to welcome top civilian performers

Many top aerobatic performers immediately signed on for this inaugural Golden Isles airshow including pilots Mike Wiskus, Michael Goulian piloting his Extra 330SC; Scott Yoak and his Quicksilver P-51D; and Buck Roetman and his yellow Christen Eagle. On the ground, Bill Braack and his Smoke-n-Thunder Jet Car will scream down the airport’s runway powered by 7,500 pounds of thrust as it races a low flying aircraft.

“All of the Smoke-n-Thunder JetCar Team is excited to be performing at the inaugural Wings Over the Golden Isle Airshow,” exclaimed Bill as we stood near his popular jet car on Monday. “JLC Airshow Management has put together a first class airshow for the Brunswick community and we look forward to performing for the tens of thousands of airshow fans that will be turning out to see the show.”

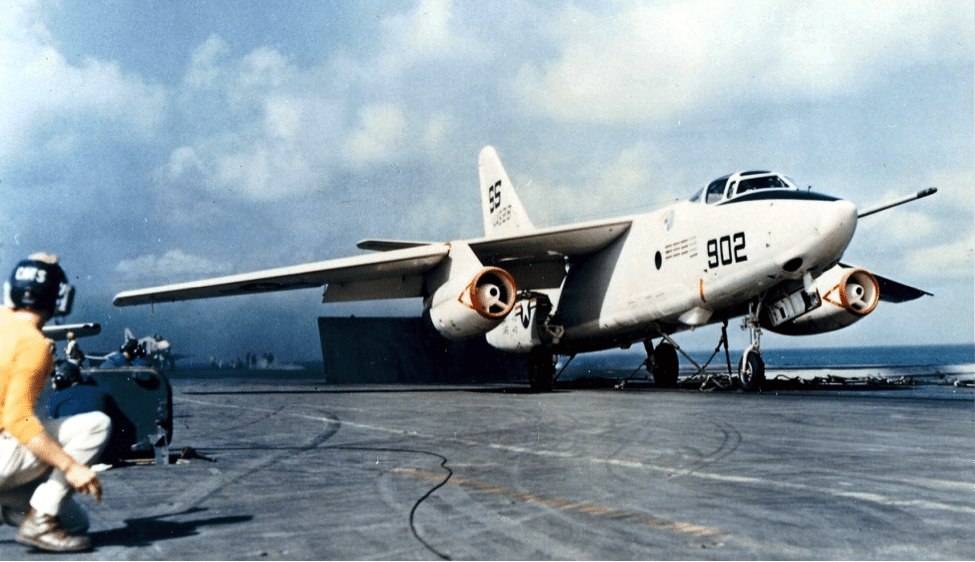

Speaking with Bill Braack, you can feel his energy as the longtime air show veteran spoke about his performances, “Driving a car that is powered by a 12,000 horsepower turbine engine is the ultimate rush. When I light the afterburner I experience more G’s than an F-18 launching off of an aircraft carrier. It is the ultimate E-ticket ride.”

The jet car pilot then turned toward the flight line with a grin and said, “I can’t wait to race Buck in his high performance Pitts aircraft at this inaugural Golden Isles airshow.”

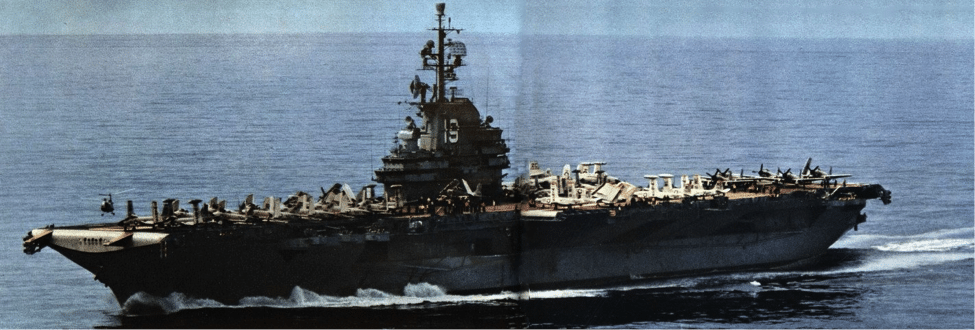

Originally constructed in 1942 by the U.S. Navy as a base for military blimps, NAS Glynco became Glynco Airport in 1975, and later Brunswick Golden Isles Airport in 2003. Today, the airport features a newly improved 8,000-foot, grooved asphalt runway used by both private, commercial, and military aircraft.

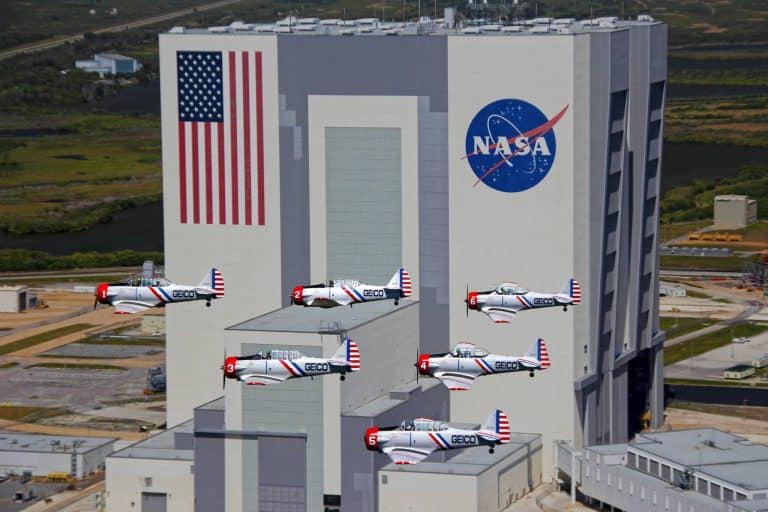

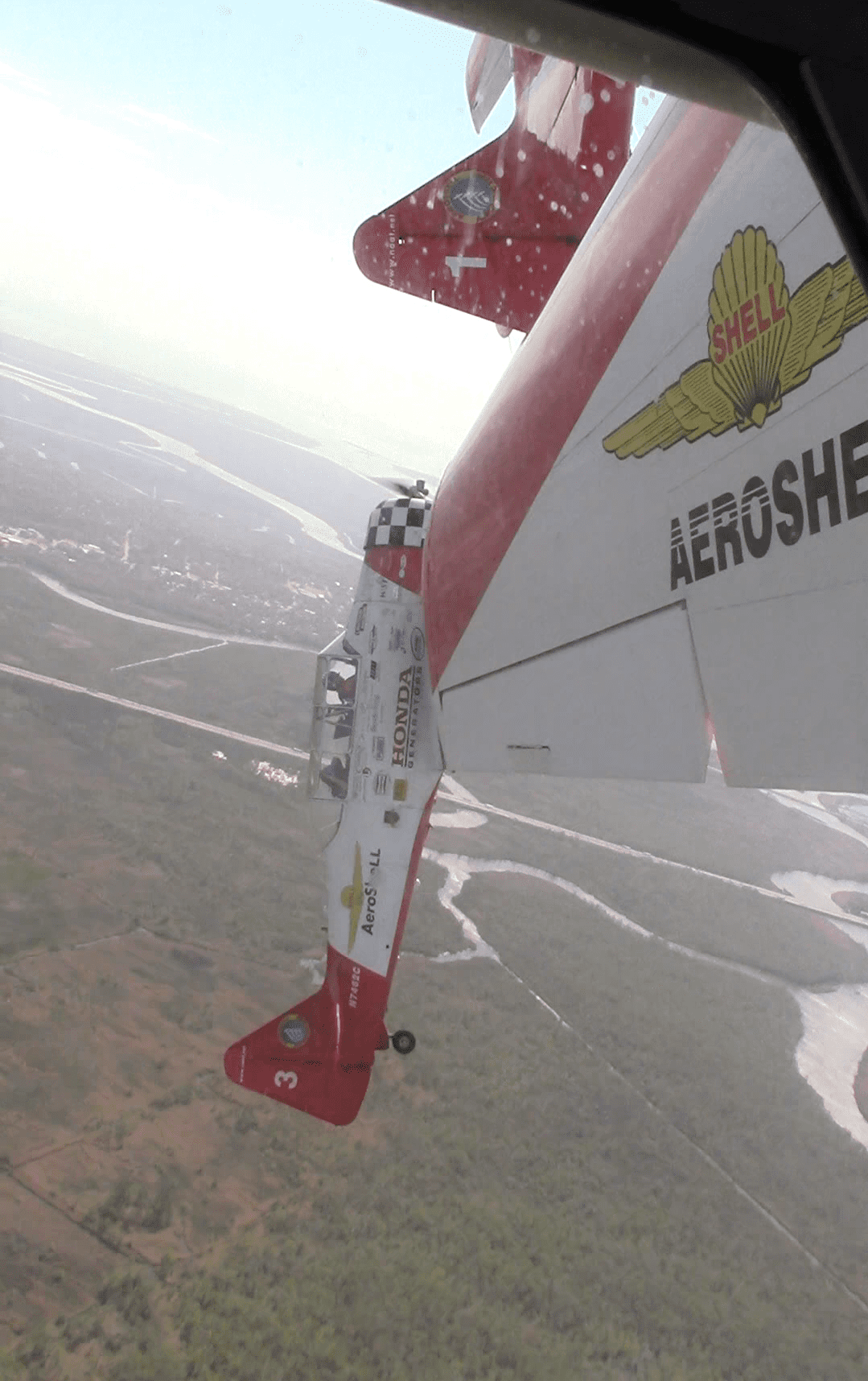

The historic flight of a squadron of World War II aircraft will come to life as Aeroshell Aerobatic Team performs each afternoon over the Brunswick airfield. The six pilots who make up this exciting demonstration team will put their AT-6 Texan through several close formation aerobatics.

“The AeroShell Aerobatic Team flies a routine similar to the modern jet teams, but we do it in World War II propeller driven advance trainers,” lead pilot of Aeroshell Mark Henley said on Monday. “We fly the North American Aviation AT-6 which was built during WWII.”

“Our airplanes are completely stock other than radio equipment and non military paint,” Henley continued as we walked past their six red and white aircraft, each sporting a checker board nose. “Most people watching our performance will notice that we keep it up close. The AT-6 will attain speeds up to 250 mph and it is nimble enough to keep the maneuvers in front of the crowd.”

Top static aircraft and a Kidz Zone

On the ground, the Navy’s F-35C Lightning II is the fifth generation strike fighter will be on display during the air show. This F-35 is a carrier variant designed for take-off and landing from an aircraft carrier. It’s for that reason the C model has a larger wingspan and can carry more fuel than the Air Force’s A Model or the Marines B model. To witness an F-35 up close is a rare treat for the public.

Other popular static displays include the Air Force’s C-17 Globemaster will be poised among the many popular aircraft on static display. A C-130 Hercules, T-38 Talon, and an F/A-18 Hornet are only a few which will be on hand to offer guests an up close view.

The popular Kid Zone near the static aircraft will allow children a fun way to pass the time during the aerobatic performances. Aircraft themed air slides, jump houses and more will be available all day during both days, air show management confirmed on Friday.

Tickets for the airshow and parking remain available online at WingsOverGoldenIsles.com, and will be sold at the gate on Saturday and Sunday beginning at 8:00 a.m. Gates open at 5:30 p.m. on Friday evening, and 9:00 a.m. on both Saturday and Sunday.

(Charles A Atkeison reports on aerospace and technology. Follow his updates on social media via @Military_Flight.)